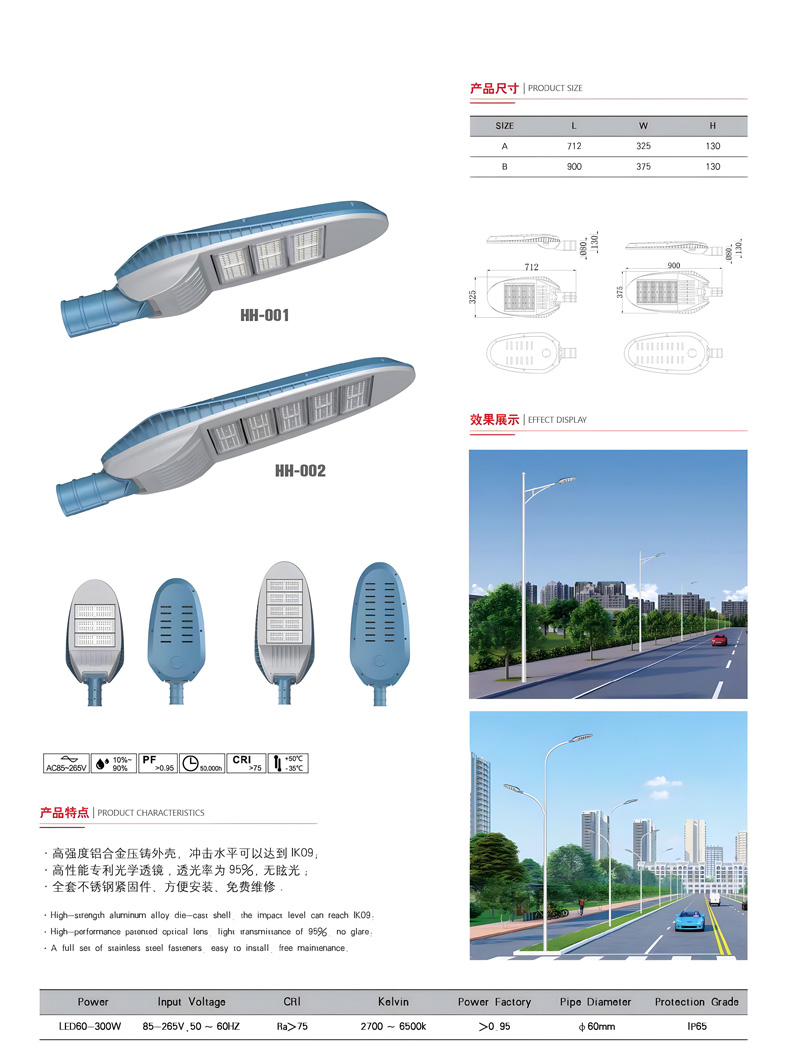

▶ Product Introduction

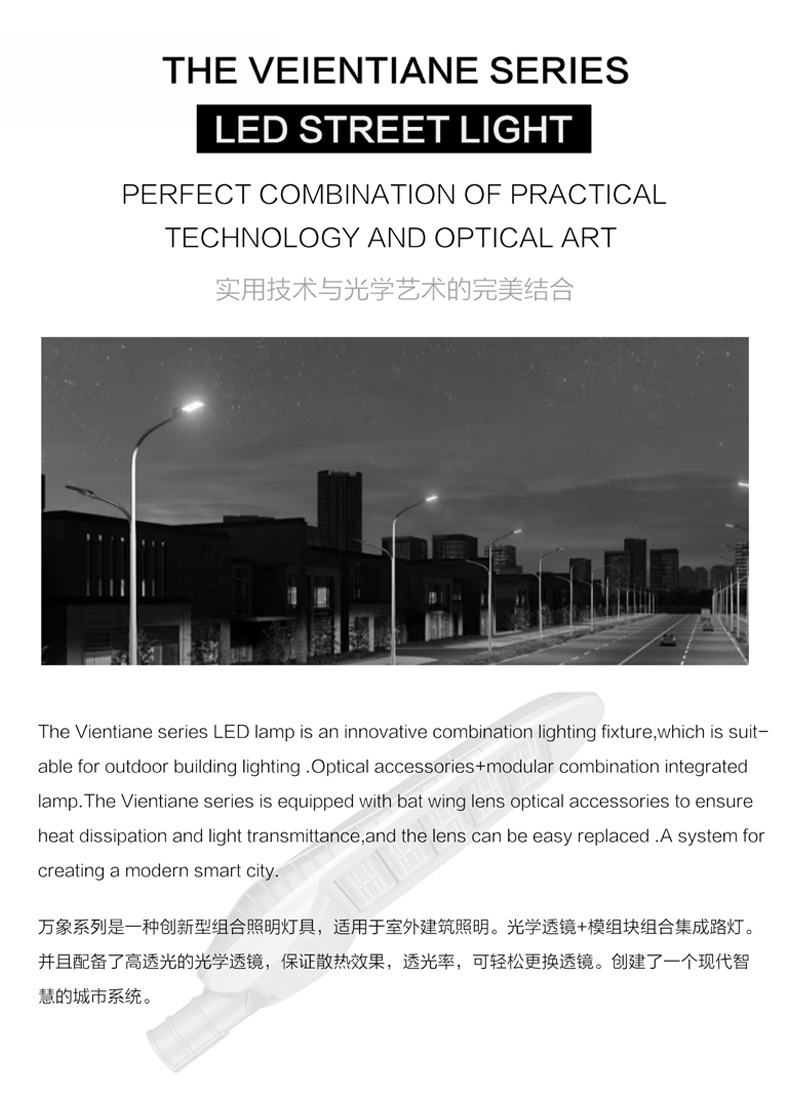

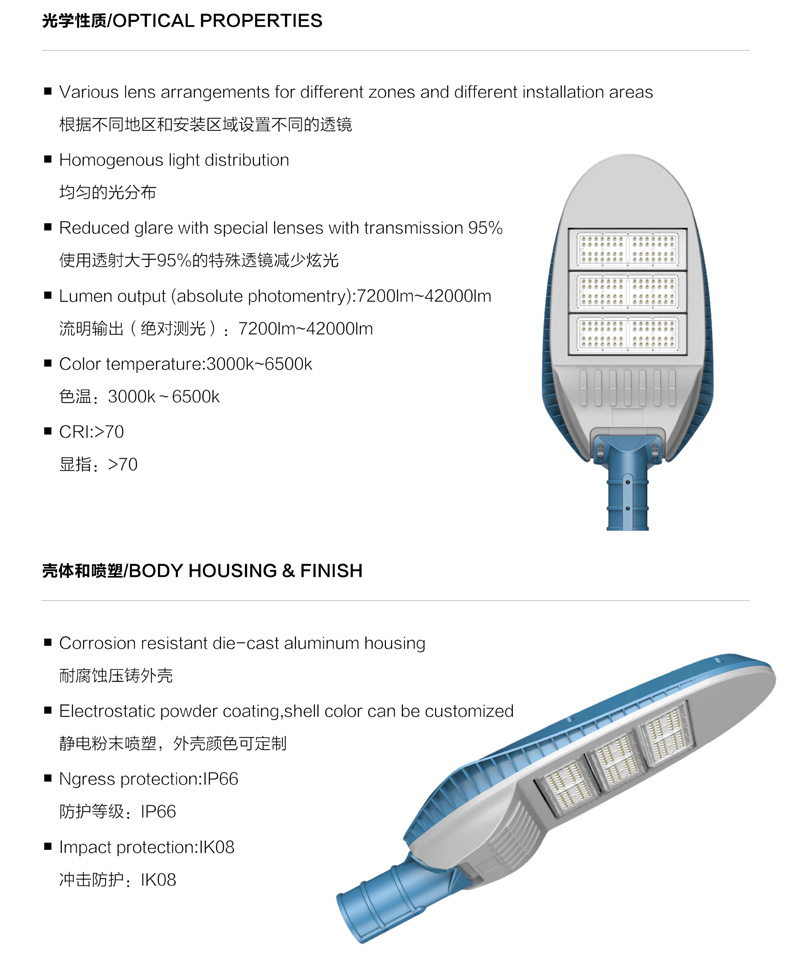

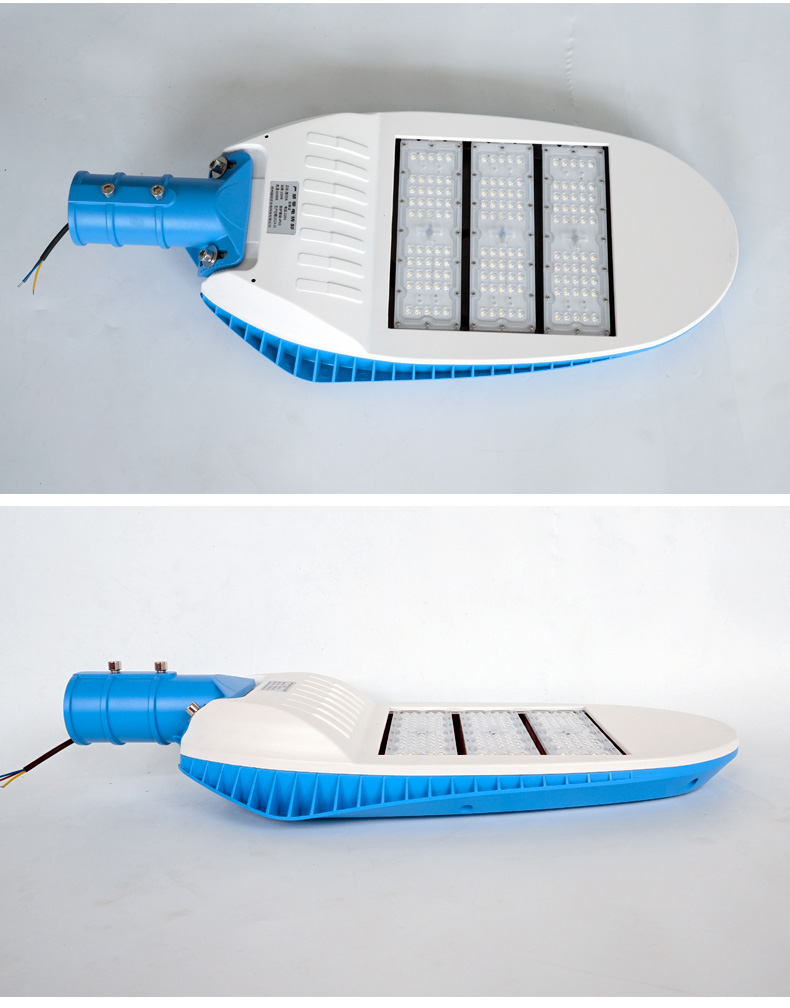

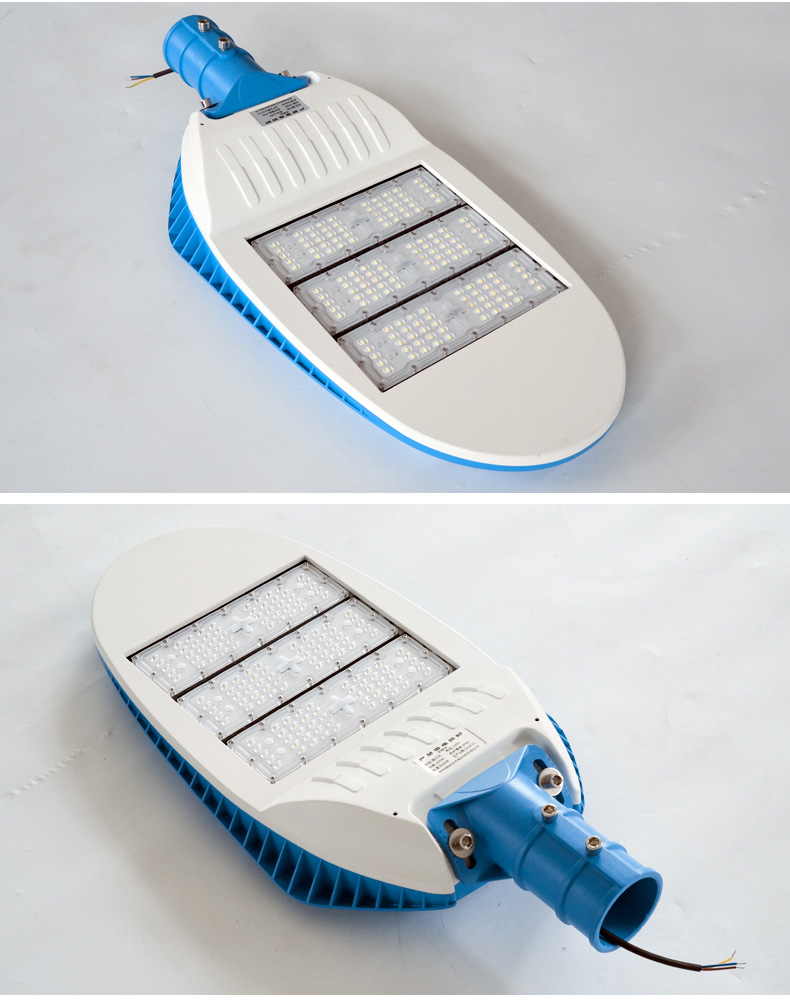

The LED lamp head is the core equipment for outdoor lighting, using high-power LEDs as the light source, suitable for urban roads, parks and other scenarios. The main body is made of aluminum alloy and is cast in one piece. It has undergone anti-corrosion treatment and has a protection level of IP65, which is waterproof and dustproof. It adopts an integrated design of the lamp shell and the heat sink, combined with a constant current source, with a lifespan exceeding 50,000 hours. The optical system precisely controls the light, saving more than 60% of electricity compared to traditional sodium lamps, and there is no glare or flicker. The startup has no delay.

▶Product Advantage

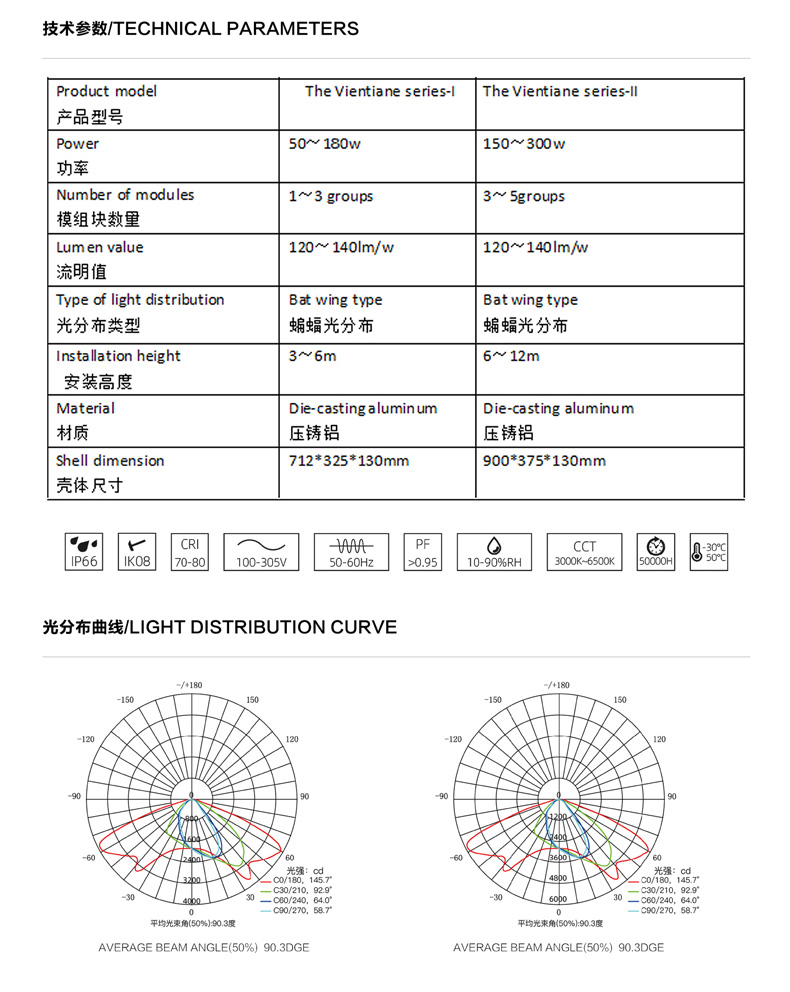

1. Extremely high energy efficiency, with energy consumption reduced by 60%+: Compared to traditional high-pressure sodium lamps, the LED street lamp heads use high-efficiency light-emitting chips, with a luminous efficiency of 130-150lm/W. In actual operation, the energy consumption is directly reduced by over 60%. Taking a 100W LED lamp head as an example, replacing a 250W sodium lamp, the annual power consumption of a single lamp drops from approximately 2190 kWh to 876 kWh. Based on an industrial electricity price of 1 yuan/kWh, the annual electricity savings per lamp exceed 1300 yuan, significantly reducing the lighting operation and maintenance costs for municipal and park users over the long term.

2. Extremely long service life, with no frequent replacements: The product adopts an integrated design of the lamp housing and heat sink, combined with aerospace-grade aluminum alloy material, improving the heat dissipation efficiency by 40%. This effectively prevents the LED chip from decaying due to high temperature. At the same time, it is equipped with a high-quality constant current drive power supply, with a voltage adaptation range of AC85-265V, and strong stability, enabling an overall service life exceeding 50,000 hours. Calculated based on 10 hours of lighting per day, it can be continuously used for more than 13 years, far exceeding the lifespan of traditional sodium lamps (8000-10000 hours), reducing the frequency of replacements and labor costs by 90%.

3. IP67 high protection, suitable for all scenarios of harsh environments: The LED street lamp heads are designed strictly in accordance with IP67 protection standards. The joint of the lamp body adopts imported silicone sealing rings, and the cover uses 8mm thick tempered glass. After undergoing -40℃ low temperature to 70℃ high temperature cycling tests, rain spray tests, and sand dust tests, it can still light up normally. Whether in northern severe cold and heavy snow, southern typhoon and heavy rain, or coastal high salt spray areas, it can operate stably and meet the outdoor lighting needs of urban main roads, rural roads, industrial parks, etc., for all scenarios.

4. Intelligent dimming control, achieving refined energy management: The lamp head is equipped with an intelligent control module, supporting 0-10V analog dimming, DALI digital dimming, or LoRa wireless communication dimming. It can automatically adjust the brightness according to different times (such as reduced traffic flow in the early morning) and different weather conditions (such as insufficient light on rainy days). The brightness adjustment range is 10%-100%. Taking municipal roads as an example, using the "100% brightness in the early morning + 50% brightness in the late morning" mode, it can save 30% of energy compared to the original energy saving, and support remote monitoring of the lamp head's operating status, achieving proactive fault warnings and reducing maintenance difficulty.

5. No glare and anti-frequency flash, ensuring road safety: Through secondary optical distribution design, the light spot of the LED street lamp head has an evenness of over 0.8, and the light can precisely focus on the road surface, with a cut-off angle controlled within 15°, effectively avoiding direct light shining on the driver or pedestrian's eyes. The glare value (UGR) is ≤19, meeting the safety standards for road lighting. At the same time, it uses high-frequency constant current drive technology, with a frequency flash depth of <3%, far below the national limit of 10%, which can reduce driver visual fatigue and lower the incidence of night traffic accidents, improving road safety.

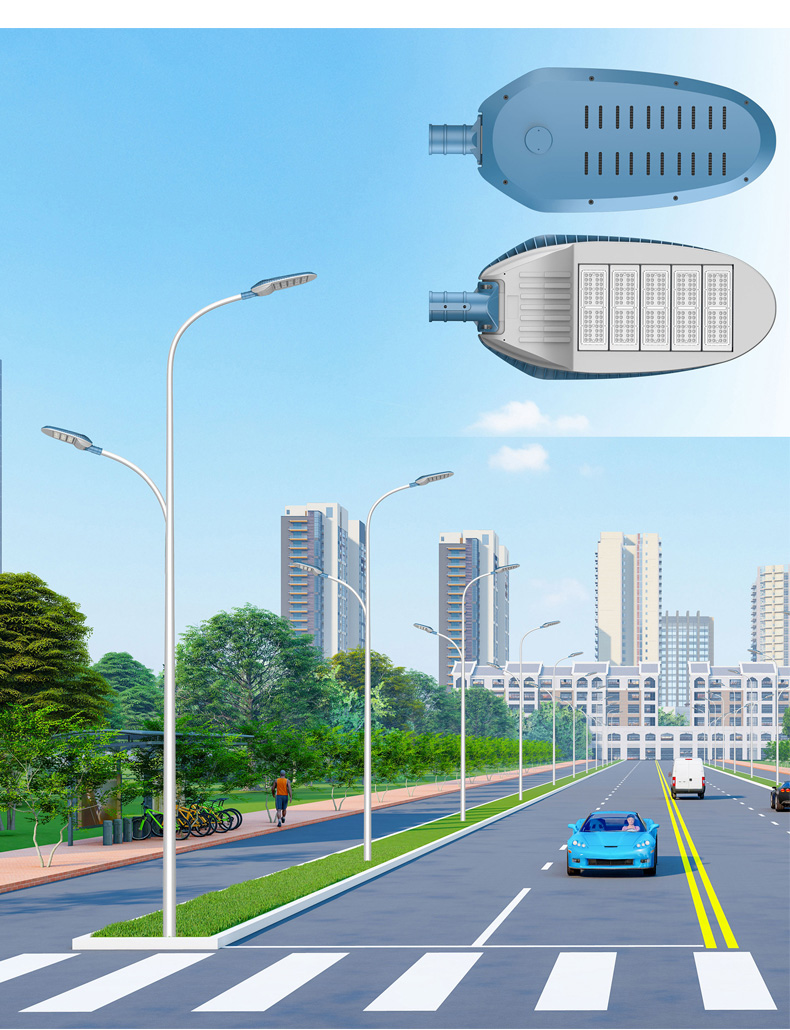

▶Product Uses

1. Urban main roads and expressways: As the core lighting equipment, they require high brightness and wide beam angle, with a luminous efficiency of over 140lm/W. Combined with anti-glare design to ensure traffic safety. They can be connected to the smart system for on-demand dimming and are suitable for scenarios with high traffic volume and high lighting requirements.

2. Rural and township roads: Often used in combination with solar systems, with low power consumption characteristics suitable for areas with weak power grids. IP67 protection can handle complex weather conditions. Medium brightness can meet the lighting needs of night pedestrians and low-speed vehicles.

3. Industrial parks and factory areas: Need to be resistant to high humidity and dust environments, with corrosion-resistant lamp bodies and stable drives to ensure long-term operation. Precise light distribution covers the periphery of workshops, storage areas, and transportation channels to enhance nighttime operation and logistics safety.

4. Parks and scenic walkways: Can be selected with medium color temperature (3000K - 4000K) to create a warm atmosphere. Through secondary light distribution to avoid light leakage. Lightweight design is suitable for landscape lamp poles and has both lighting function and environmental coordination.

5. Squares and parking lots: Adopt wide-angle floodlight design to achieve uniform lighting over a large area, with a luminous intensity of over 20lux. Support intelligent control, which can adjust brightness according to the flow of people and vehicles, balancing safety and energy conservation.

▶Product Operate Guide

1. Cut off the power supply to ensure safety, remove the old lamp head (if any); 2. Align the LED lamp head mounting bracket with the lamp pole interface and fix it with bolts;

3. Connect the power cord, distinguish the positive and negative poles and take insulation measures;

4. After checking the installation stability, turn on the power supply, test the brightness and switch function of the lamp head, and confirm that everything is normal before completing the installation.

Subscribe to our newsletter