▶ Product Introduction

The LED double-arm street lamp is an outdoor lighting device equipped with two LED light sources. The double-arm design expands the illumination range and ensures uniform light without blind spots. It uses high-efficiency LED chips, which have strong energy-saving performance. Combined with an anti-corrosion lamp body and IP65 waterproof feature, it can withstand harsh weather conditions and is suitable for urban roads, residential areas, and other scenarios, safeguarding nighttime safety.

▶Product Advantage

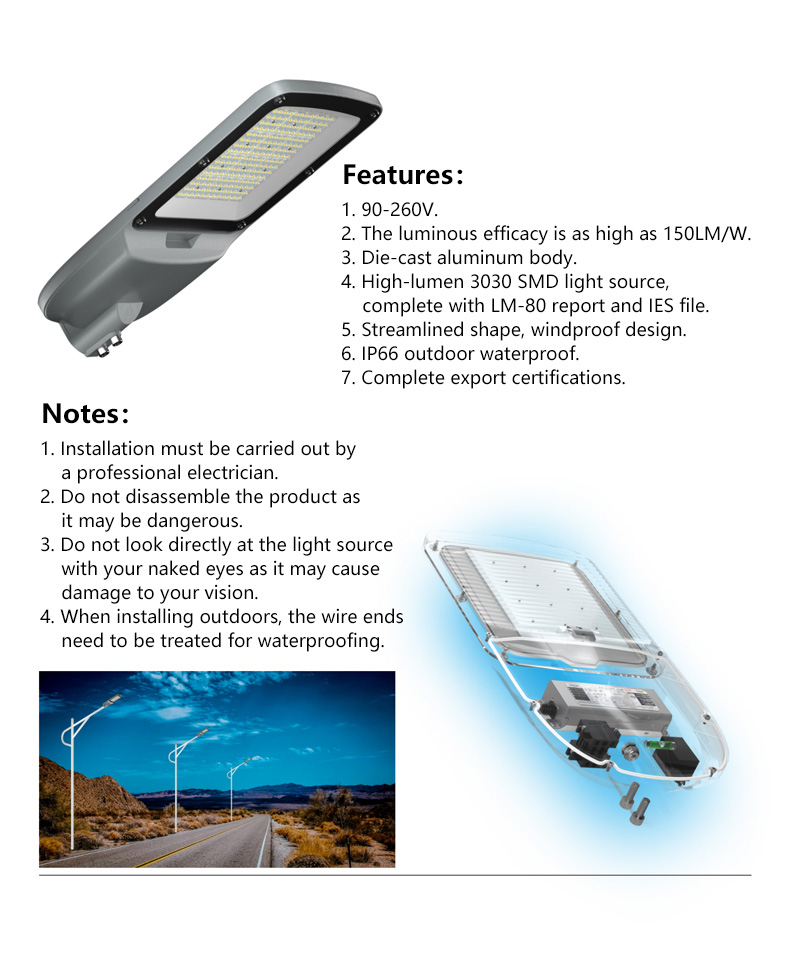

1. High efficiency, energy-saving, and environmentally friendly: Using imported LED chips, the light output reaches over 130lm/W, which is 60% more energy-efficient than traditional high-pressure sodium lamps. The annual power consumption is as low as 85 kWh, and it does not contain harmful substances such as mercury and lead, meeting the needs of municipal road energy-saving renovation and contributing to carbon neutrality.

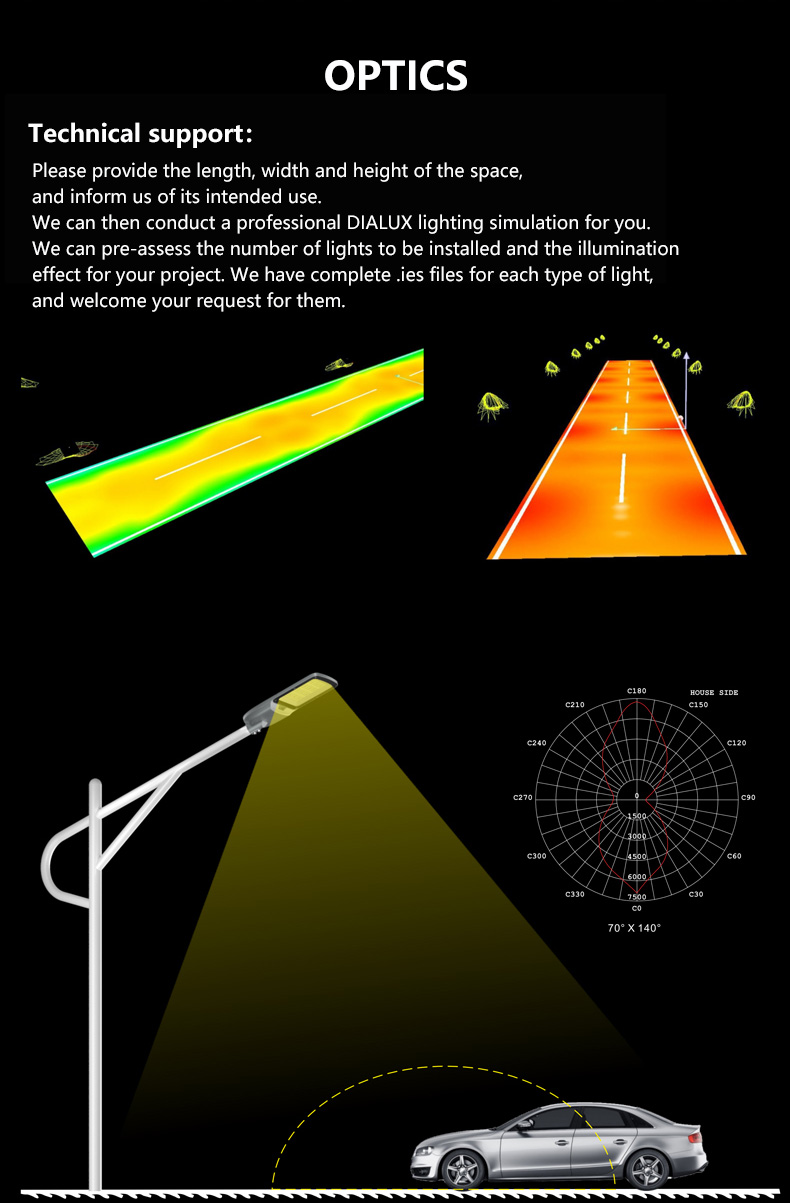

2. Dual-light source design, no blind spots in lighting: Each light arm is equipped with an independent light source, and the illumination angle can be adjusted as needed, covering a width of 18-25 meters. The uniformity of road illumination is ≥0.7, and the color rendering index Ra is ≥80, which can clearly reproduce the road conditions and enhance the safety of nighttime urban road lighting.

3. Super durable structure, adaptable to harsh environments: The lamp body is made of ADC12 die-cast aluminum alloy, with an anti-corrosion grade of WF2, capable of withstanding temperature differences of -30℃ to 60℃. Combined with IP67 waterproof design, the wind resistance level is 12 grades. It can still operate stably in rainy and typhoon weather, reducing maintenance frequency.

4. Intelligent control, convenient management: It supports RS485/LoRa communication protocols and can be connected to the smart street lamp management system. Remote control for switching, dimming, and fault alarm can be achieved. It can also statistically collect energy consumption data, increasing the efficiency of single-lamp management by 80% and reducing labor inspection costs.

5. Long lifespan, low failure rate, and high cost-effectiveness: The LED light source has a lifespan of over 50,000 hours, which is more than three times that of traditional street lamps. The drive power supply adopts a wide-voltage design (AC85-265V), with a failure rate of less than 0.5%, and the average fault-free working time is up to 40,000 hours. It is more cost-effective for long-term use.

▶Product Uses

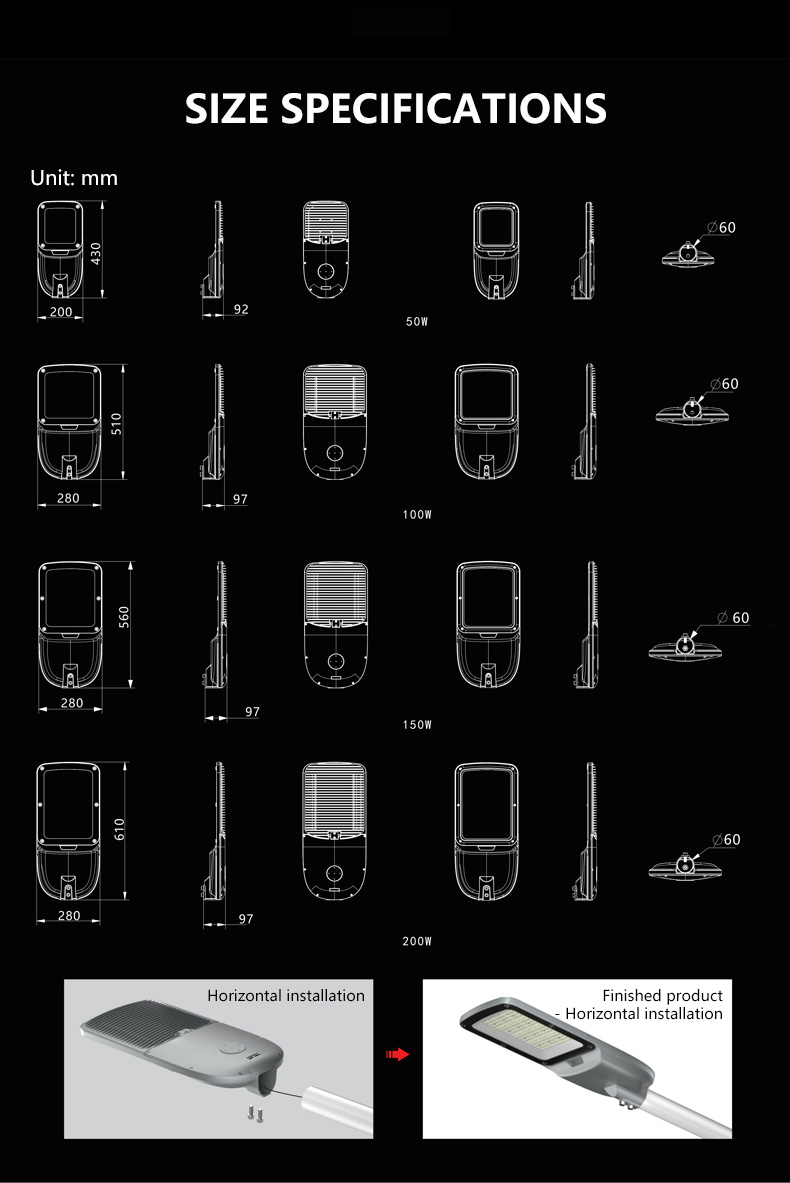

1. Main roads and national highways: Compatible with 6-12 meter lamp poles, symmetrical or differently-heighted arm designs can accommodate both motor vehicle and non-motor vehicle lanes, with a light coverage width of up to 25 meters, meeting road lighting standards and ensuring safe passage during peak traffic hours.

2. Municipal squares and parks: Customizable with a landscape appearance that integrates local elements, dual light sources provide uniform and soft light, compatible with public spaces such as Chang'an Square, featuring both lighting and urban image display functions.

3. Large communities and residential areas: Low-glare dual-arm layout, capable of adjusting the lighting intensity for different areas (e.g. vehicle lanes and pedestrian areas), creating a warm atmosphere, with the 8-meter standard specification suitable for main roads in residential areas, enhancing residents' sense of security during nighttime activities.

4. Industrial parks and suburban roads: Anti-corrosion and wind-resistant structure compatible with complex environments such as factory areas and national highways, supporting solar power supply upgrades, capable of stable operation in suburban or factory area roads without power grid coverage, reducing energy consumption.

5. Pilot sections of smart municipal roads:预留 5G、监控等集成接口, can be connected to the cloud control platform for remote management, compatible with smart road projects such as Jin Yi Central Avenue, helping to implement smart city infrastructure

▶Product Operate Guide

1. Power off and test for electricity: Before construction, disconnect the power supply in the work area and use an electric tester to confirm there is no electricity.

2. Assembly and fixation: First, assemble the lamp arms and lamp heads on the ground, then lift and fix them onto the lamp pole as a whole to avoid the risk of high-altitude assembly.

3. Wiring inspection: Connect the neutral and live wires according to the specifications, wrap insulating tape, and test the circuits with a multimeter before powering on. If there are no faults, then close the switch.

4. Acceptance inspection: Confirm that the lamp pole is stable and the lamp is functioning normally, and complete the installation.

Subscribe to our newsletter